TL;DR – How to Start Knife Making

- Knife making is a rewarding craft that begins with a few essential tools and materials like steel, files, a grinder, and patience.

- You can start with a simple stock removal method before progressing to forging if you choose.

- Different blade designs serve different functions—form should follow function.

- Knife care is just as important as the build; use wax or oil, such as Pelican Paste, to protect your finished blades.

- Find hands-on knife making classes near you at LearnMake.us and learn from experienced instructors.

Beginning Knifemaking – What Equipment Do I Need?

Knife making is more than just a hobby. It’s a hands-on journey into craftsmanship that blends creativity, skill, and tradition. Whether you’re looking to forge blades in your backyard or work with precision in your garage, this guide will walk you through the basics of knife making—from essential tools to blade design and maintenance—so you can get started with confidence.

The Enthralling Journey of Knife Making

Knife making has attracted people from all walks of life. Whether it’s the thrill of forging steel with fire or the calm precision of shaping a knife by hand, there’s something incredibly rewarding about crafting your own blade. Many makers say that knife making becomes a lifelong passion—and it all begins with the right knowledge and equipment.

Essential Tools

Before you can create a knife, you’ll need to gather some essential tools. Your setup will depend on your skill level and whether you want to forge your blade or use stock removal methods.

Where to Buy Knife Making Steel and Supplies

You can buy quality knife steel and knife making supplies online from trusted suppliers like:

- New Jersey Steel Baron (NJSB)

- Maritime Knife Supply

- Jantz Supply

- Texas Farrier Supply

- Pops Knife Supply

- and much more…

These suppliers offer beginner-friendly options and high-quality steels commonly used in knife making.

Starter Kit

A basic knife making kit for beginners should include:

- A 1×30” belt sander or file set

- be sure to use ceramic belts

- 1084 high carbon steel (easy to heat treat)

- Angle grinder

- A vise

- Drill and carbide drill bits

- Clamps

- Epoxy for handles

- Safety gear (gloves, eye protection, dust mask)

You can start with a stock removal method using files and sandpaper—perfect for small spaces or low budgets.

Intermediate Kit

As you grow, you might upgrade to:

- 2×72” belt grinder

- Pre-built grinders (Ameribrade)

- DIY Kit (Housmade.us)

- Heat treating oven or forge

- Band saw or metal cutting saw

- Digital calipers

- Drill Press

These tools help increase speed and precision, allowing you to move beyond the basics.

Forging Kit

For those who want to forge their own blades:

- Propane forge or coal forge

- Anvil (even a railroad track piece can work)

- Hammer (2–4 lb cross-peen or rounding hammer)

- Tongs and fire-resistant gloves

- Vise

- Quench tank

Forging takes more skill and ,arguably, time but it’s a deeply satisfying way to shape steel by hand. This is a great beginner forge. But if you want something more serious, check out the Apollo Forge by Housemade.

Understanding Blade Designs: From the profile to the grind

Different knives are made for different purposes. Whether you’re making a chef’s knife, hunting blade, or pocket knife, form should always follow function.

- Drop Point – Great all-around design for hunting and utility.

- Clip Point – Ideal for piercing tasks; common in bowie knives.

- Sheepsfoot – Safe, easy to control; used in rescue knives.

- Tanto – Strong tip for tactical uses.

- Chef’s Knife – Curved edge for rocking cuts; essential in the kitchen.

This is just scratching the surface on what terms you will come across as you start you knife making journey.

Research your chosen design, and think about how the blade will be used. A well-designed knife combines balance, comfort, and utility.

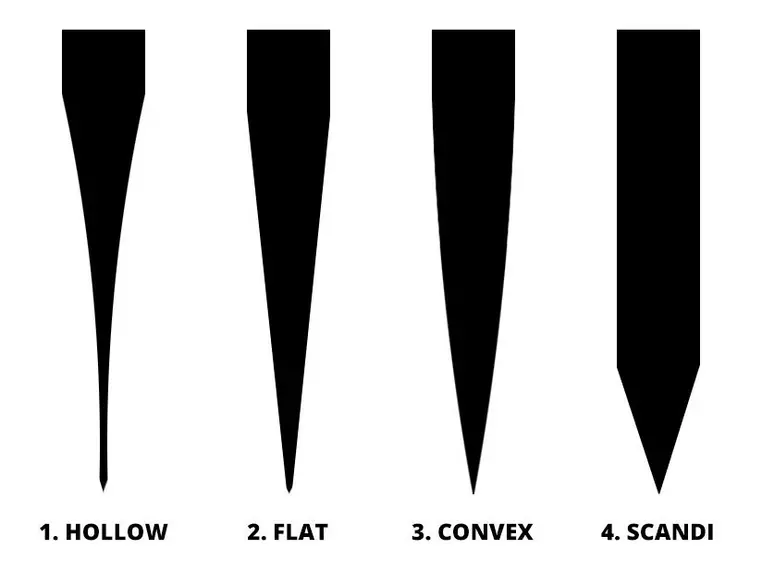

There is also a myriad of grinds that can be done on a knife. Intended function dictates what grind you might use on a blade, but here are some beginner friendly grinds you should start with.

- Flat grind – Just what it sounds like. It is a flat bevel from the edge to the spine. It is harder than it sounds to have a truly flat grind, but it is the easiest concept to wrap your head around.

- Convex grind – A convex edge has a slight curve from edge to spine. It is a great grind for edge retention.

- Scandi grind – This is kind of like a flat grind, but the ground portion of the bevel only goes a quarter of the way up the side of the blade or so.

- Hollow grind – I actually wouldn’t recommend this grind for the beginner. Just understand what it is for now. It is great for kitchen knives and more delicate and precise cuts.

Here is an image of the cross section of these grinds to help you better understand them.

The Process: Turning Raw Material into a Functional Tool

Knife making has two primary methods of shaping steel:

Forging vs Stock Removal

- Forging involves heating steel and hammering it into shape. This method offers full control over the shape and structure but requires more tools and heat management. One main benefit to forging is that it is an effective way to use material. Stock removal tends to ‘waste’ more steel in the process, as forging allows you to utilize a piece of steel more efficiently.

- Stock Removal means grinding or filing a blade from a flat piece of steel. It’s faster and more beginner-friendly but limits some design flexibility.

Both are valid techniques. Many beginners start with stock removal and later move to forging as they gain confidence.

Knife Care: Care for What You Worked So Hard to Make

Taking care of your handmade knife ensures it stays sharp, rust-free, and beautiful for years.

Wax vs Oil

- Wax: A high-quality wax like Pelican Paste offers a thin, durable, food-safe protective coat for both tools and kitchen knives. It doesn’t rub off easily and helps prevent moisture damage.

- Oil: Common oils like mineral oil are easy to apply but wear off faster and require frequent reapplication.

Many makers prefer wax for its longevity and clean finish, especially on wooden handles and carbon steel blades.

The Reward of the Craft

Knife making teaches patience, problem-solving, and creativity. The moment you hold a blade you made from scratch is deeply satisfying. Over time, your skills will grow—and so will your collection of beautiful, functional knives.

Some makers turn their craft into a side business, selling knives at markets or online. Others simply enjoy the peace of working with their hands. Either way, the rewards are personal and lasting.

How to Find a Knife Making Class

If you want to learn in person, hands-on knife making classes are one of the best ways to start. You’ll gain experience with tools, get tips from experts, and avoid common mistakes.

Visit LearnMake.us to find a knife making class near you. LearnMake partners with skilled instructors across the country to help beginners and hobbyists get started the right way.

FAQ About Knife Making

Q: What is the best steel for beginners?

A: 1084 high carbon steel is forgiving, easy to heat treat, and widely recommended for beginners.

Q: Do I need a forge to make a knife?

A: No. You can use the stock removal method with basic tools like files or belt sanders and still create a high-quality knife.

Q: How long does it take to make a knife?

A: A simple knife can take 8–20 hours, depending on your tools and methods. Forged blades may take longer due to additional steps.

Q: What safety gear do I need for knife making?

A: Always wear eye protection, hearing protection, and a dust mask. Proper ventilation is also important when grinding or working with epoxy.

Q: Can I take a knife making class near me?

A: Yes. LearnMake makes it easy to find local knife making classes. Just visit LearnMake.us and enter your location.

Q: What is LearnMake?

A: LearnMake is a platform that connects people with hands-on crafting classes—including knife making. Whether you’re a total beginner or looking to level up your skills, LearnMake helps you find expert instructors and supportive workshops across the country.

Ready to start your knife making journey? Gather your tools, choose your steel, and take the first step toward a rewarding new craft. Or better yet—sign up for a class near you at LearnMake.us and learn from real makers who’ve been there.